KLD-MK Series

Low-voltage Power Capacitor

An innovative inflatable self-healing explosion-proof capacitor that adopts both safe and environmental protection technologies, with lower losses and smaller size.

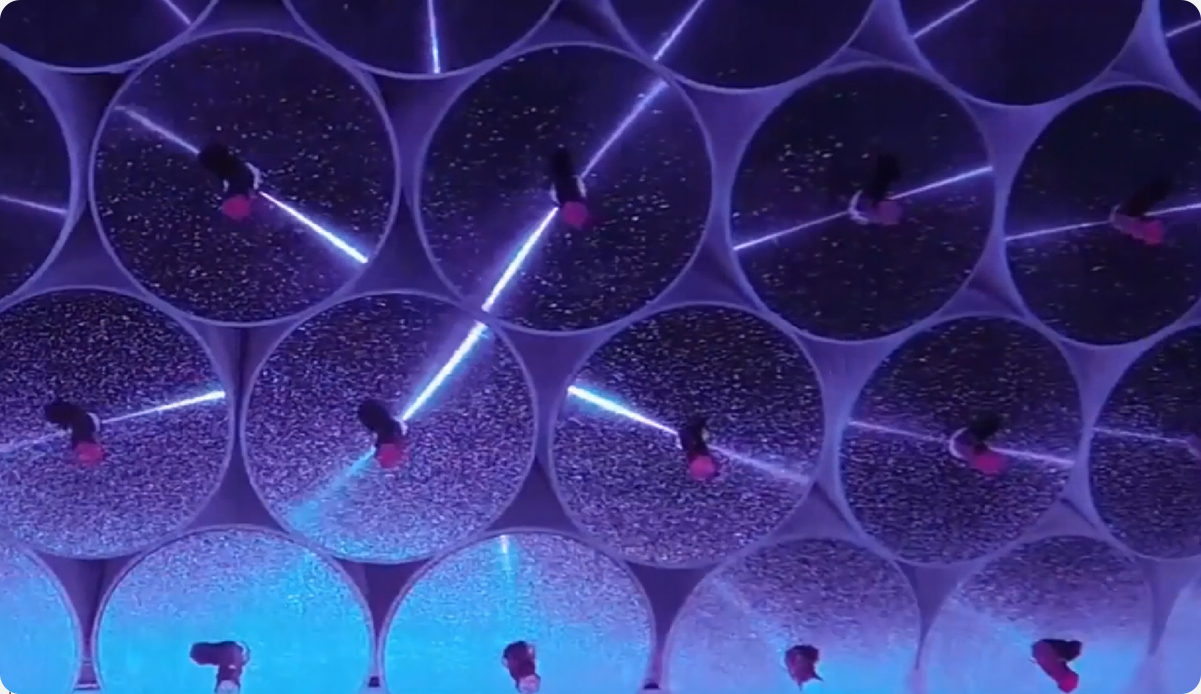

KLD series low-voltage capacitor is characterized by an innovative cylindrical explosion-proof function that uses gradient metallized polypropylene film technology to ensure windings with ideal self-healing characteristics. We use gas instead of conventional dielectrics such as oil and resin, and dry technology to meet the higher requirement for environmental protection and safety as well as small size.

The operating stability of the capacitors is ensured by long-term vacuum drying technology. Unique vacuum evaporation and corrugated cutting technology and optimized winding sequencing make our capacitors not only have outstanding capacity-to-volume ratio, but also have strong capability to withstand AC, effective and peak current impacts. Portable assembly method and good heat dissipation ensure a greater degree of installation space saving while removing harmonic hazards and correcting power factor.

The technical design, testing and use of the product are in compliance with GB12747.1/GB12747.2/IEC60831 standards, with CE certificate and ROHS environmental certificate.

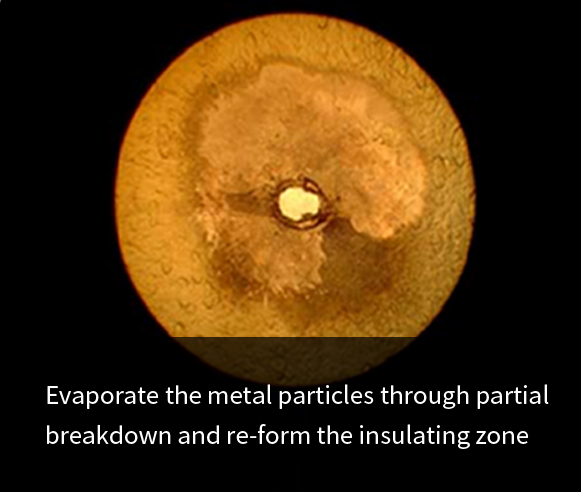

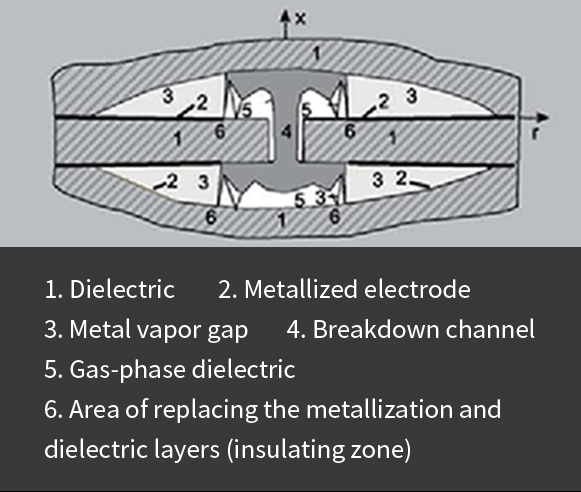

Capacitor winding dielectric is made of gradient metallized polypropylene film. It evaporates metal particles through partial breakdown and re-form the insulating area, so that the capacitor isolates the fault point on its own and continues to work normally, achieving the self-healing function. At the same time, the capacity loss due to breakdown is negligible and does not affect the normal operation of the capacitor.

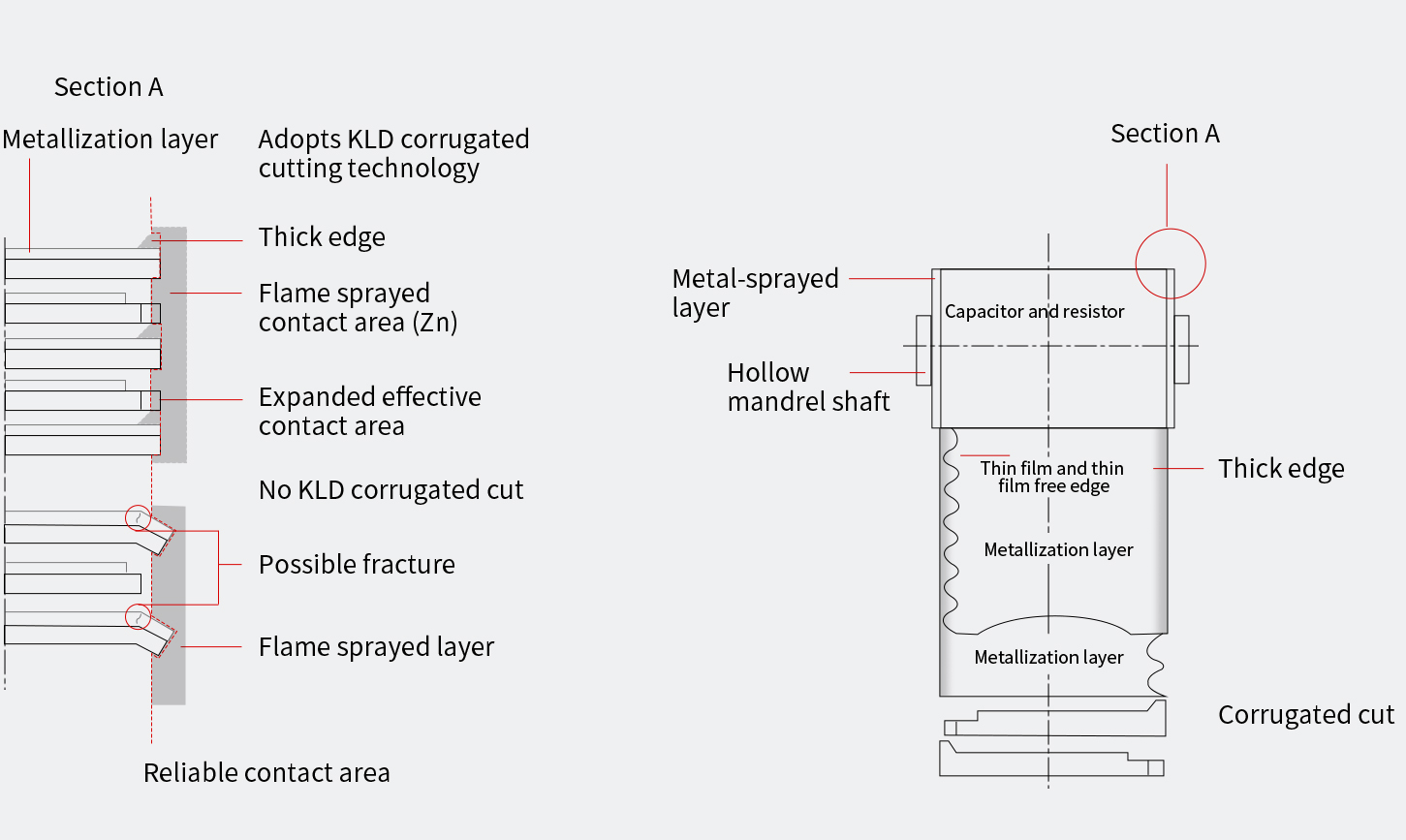

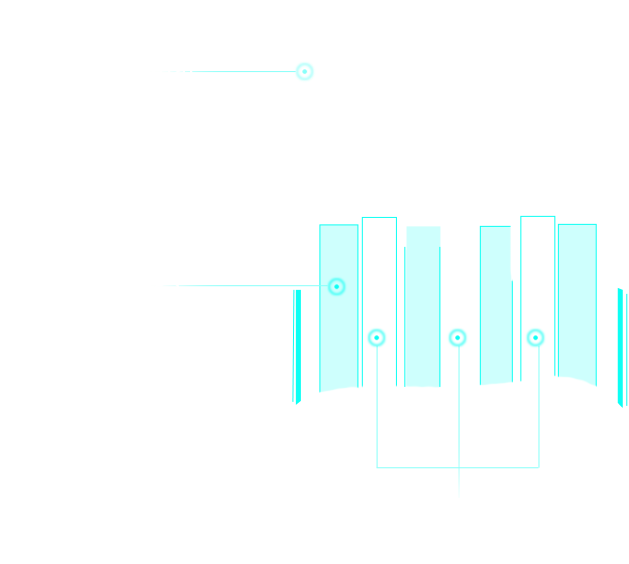

Capacitor adopts film edge thickening reinforcement technology, which can enhance the reliable connection between the gold-sprayed surface and the electrode. The internal film uses both corrugated and smooth cutting methods, which maximizes the effective surface between the component and the metallization layer and improves surge current suppression capability.

Fine zinc powder particles are injected into into the end face of the component by high-speed gold-sprayed technology and formed into a delicate gold-sprayed surface, on which you can lead out the electrode. In the whole process, each winding group should strictly control the thickness and flatness of the gold-sprayed layer to achieve the effect of low loss, stable performance and long service life.

According to GB12747/IEC60831 standards, each capacitor has strictly passed the factory routine test: each three-phase capacitor terminal is equipped with an end cover that can prevent your fingers contact with the live component by accident. Also, it is combined with a discharging compartment, which can protect the personal safety of the personnel at the site.

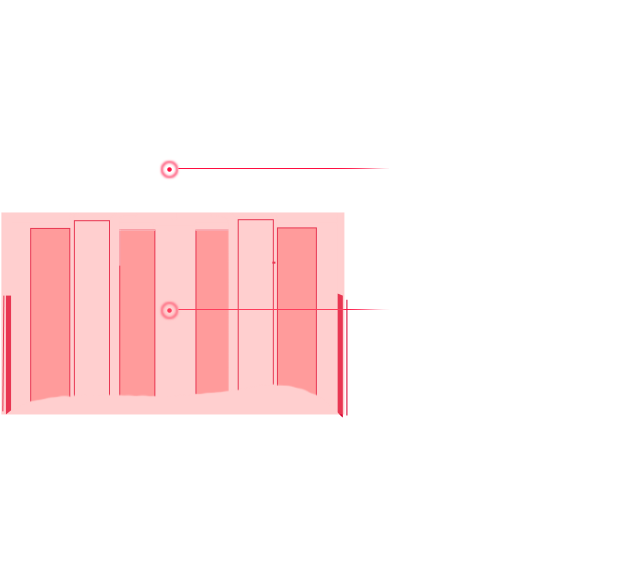

KLD-MK series capacitors have a cylindrical aluminum can case with a "pressure-relief structure" inside. Pressure can be relieved by pushing up the top of the capacitor. At the same time, the internal metal wires are pulled off, effectively blocking current flow and isolating the capacitor.

| Rated voltage | 230~1000V,50/60Hz |

| Overvoltage | 1.1Un(long term), 1.15Un(30min), 13Un(5min) |

| Overcurrent | 2.0In |

| Surge current | 500In |

| Capacitance tolerance | ±5% |

| Dielectric | High-quality polypropylene film |

| Perfusion material | Inert insulating material gas, nitrogen gas |

| Dielectric loss | ≤0.1W/kvar |

| Safety features | Dry technology, overvoltage isolator, self-healing |

| Discharge time | Discharge to below 50V in 50s with discharge resistance |

| External structure | Cylindrical aluminum metal shell with safety bolts at the bottom |

| Ambient temperature | -40/D; max. temperature +55°C, average daily max. +45°C, average annual max. +35°C, min. -40℃ |

| Cooling method | Natural or forced cooling |

| Installation position | Anywhere, bottom bolt grounding |

| Relative humidity | ≤95% |

| Altitude | Conventional 2,000 meters (customized for higher altitude) |

| Protection degree | IP20, Indoor assembly (installed with the cover that meets IPS4) |

| Service life | >200000h |

| Technical Standards | Complies with GB12747,IEC60831,VDE0560-46/47 |

| Model | Capacity(kvar) | Loss(W/kvar) | Designed service life(h) |

| Single-phase | |||

| KLD-MK-5-1-280V | 5 | ≤0.1 | 200,000 |

| KLD-MK-10-1-280V | 10 | ≤0.1 | 200,000 |

| KLD-MK-15-1-280V | 15 | ≤0.1 | 200,000 |

| KLD-MK-5-1-300V | 5 | ≤0.1 | 200,000 |

| KLD-MK-10-1-300V | 10 | ≤0.1 | 200,000 |

| KLD-MK-15-1-300V | 15 | ≤0.1 | 200,000 |

| Three-phase | |||

| KLD-MK-12.5-480V | 12.5 | ≤0.1 | 200,000 |

| KLD-MK-15-480V | 15 | ≤0.1 | 200,000 |

| KLD-MK-20-480V | 20 | ≤0.1 | 200,000 |

| KLD-MK-25-480V | 25 | ≤0.1 | 200,000 |

| KLD-MK-30-480V | 30 | ≤0.1 | 200,000 |

| KLD-MK-12.5-525V | 12.5 | ≤0.1 | 200,000 |

| KLD-MK-15-525V | 15 | ≤0.1 | 200,000 |

| KLD-MK-20-525V | 20 | ≤0.1 | 200,000 |

| KLD-MK-25-525V | 25 | ≤0.1 | 200,000 |

| KLD-MK-30-525V | 30 | ≤0.1 | 200,000 |

Rated voltage:230~1000V,50/60Hz

Overvoltage:1.1Un(long term), 1.15Un(30min), 13Un(5min)

Overcurrent:2.0In

Surge current:500In

Capacitance tolerance:±5%

Dielectric:High-quality polypropylene film

Perfusion material:Inert insulating material gas, nitrogen gas

Dielectric loss:≤0.1W/kvar

Safety features:Dry technology, overvoltage isolator, self-healing

Discharge time:Discharge to below 50V in 50s with discharge resistance

External structure:Cylindrical aluminum metal shell with safety bolts at the bottom

Ambient temperature:-40/D; max. temperature +55°C, average daily max. +45°C, average annual max. +35°C, min. -40℃

Cooling method:Natural or forced cooling

Installation position:Anywhere, bottom bolt grounding

Relative humidity:≤95%

Altitude:Conventional 2,000 meters (customized for higher altitude)

Protection degree:IP20, Indoor assembly (installed with the cover that meets IPS4)

Service life:>200000h

Technical standards:Complies with GB12747,IEC60831,VDE0560-46/47

Single-phase

Capacity(kvar):5

Loss(W/kvar):≤0.1

Designed service life(h):200,000

Capacity(kvar):10

Loss(W/kvar):≤0.1

Designed service life(h):200,000

Capacity(kvar):15

Loss(W/kvar):≤0.1

Designed service life(h):200,000

Capacity(kvar):5

Loss(W/kvar):≤0.1

Designed service life(h):200,000

Capacity(kvar):10

Loss(W/kvar):≤0.1

Designed service life(h):200,000

Capacity(kvar):15

Loss(W/kvar):≤0.1

Designed service life(h):200,000

Three-phase

Capacity(kvar):12.5

Loss(W/kvar):≤0.1

Designed service life(h):200,000

Capacity(kvar):15

Loss(W/kvar):≤0.1

Designed service life(h):200,000

Capacity(kvar):20

Loss(W/kvar):≤0.1

Designed service life(h):200,000

Capacity(kvar):25

Loss(W/kvar):≤0.1

Designed service life(h):200,000

Capacity(kvar):30

Loss(W/kvar):≤0.1

Designed service life(h):200,000

Capacity(kvar):12.5

Loss(W/kvar):≤0.1

Designed service life(h):200,000

Capacity(kvar):15

Loss(W/kvar):≤0.1

Designed service life(h):200,000

Capacity(kvar):20

Loss(W/kvar):≤0.1

Designed service life(h):200,000

Capacity(kvar):25

Loss(W/kvar):≤0.1

Designed service life(h):200,000

Capacity(kvar):30

Loss(W/kvar):≤0.1

Designed service life(h):200,000